A few questions about the packaging machine package is not good

Packaging machine failure is more likely to occur in the problem of bad packaging roll, and there are many factors affecting this problem

1. The packaging rolls are unqualified and not produced by regular manufacturers. The probability of bad packaging caused by this problem is 97.35%

Maintenance measures: use Donghua original regular packaging roll.

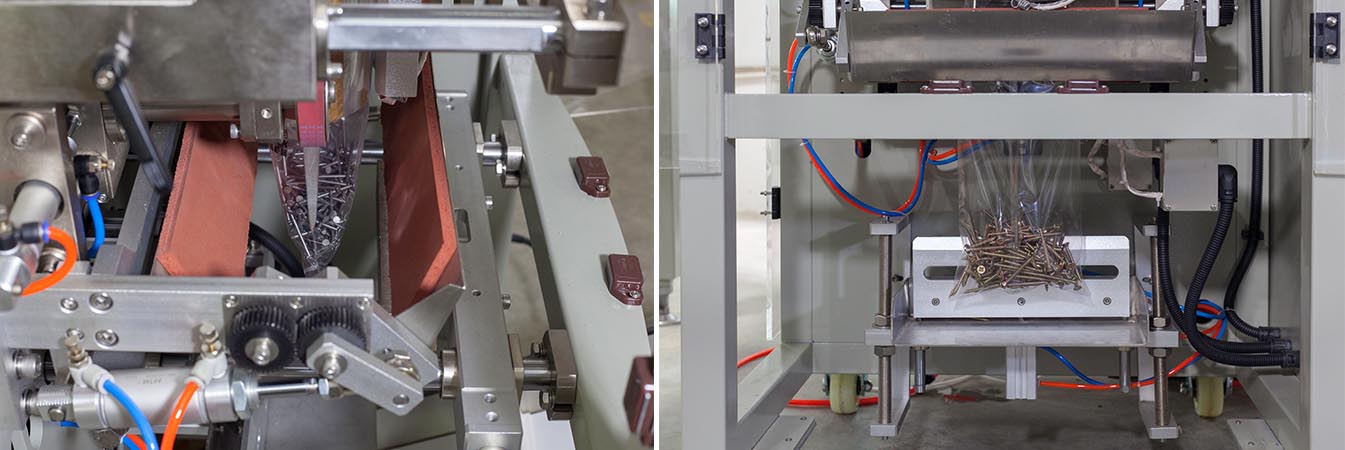

Regular packaging roll pattern:

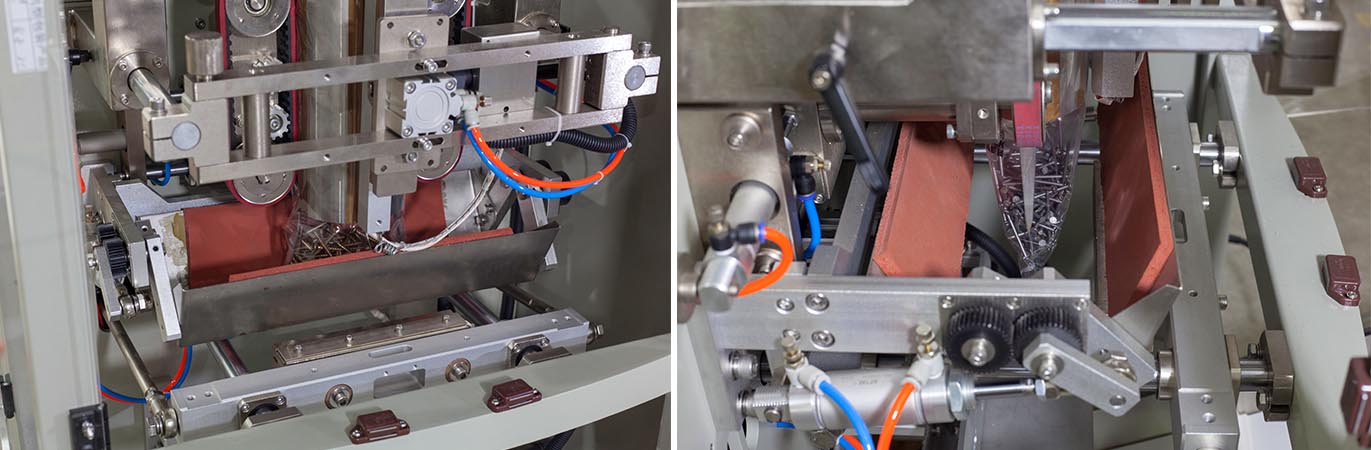

2, the packaging roll is not loaded, there are two cases

One is that the packing rolls are not packed in the normal way

For example, the bag is inverted (causing hot bag, roll onto the shaft sticky)

For example, do not wrap the shaft volume (two pages will appear to be inconsistent and cause scalding or scalding)

Trapped packaging coil spring is too tight (small packaging, cut from the middle or wrinkled packaging)

Repair measures: the correct installation of the packaging volume, the correct installation method: two is installed the volume, but the corners appear fold, so that the packaging volume is easy to packaging edge scalding, and cause the package is not good

Repair measures: Just flatten the folds on the edge of the package

3. Motor problem: the upper (lower) motor of the packaging machine may not rotate

The upper motor does not rotate (the package will be cut into small pieces, and the phenomenon of pulling the bag)

The next motor does not turn (there will be no sealing, note: stuck knife will also appear motor does not turn) 150 packaging machine type will only appear behind the situation

Maintenance measures: Repair the motor

4. The two faces of the packaging roll are not even (the packaging will be wrinkled with scalding)

Maintenance measures: a timely use of dry steel wire ball to clean hot plastic when the shaft of the packaging machine is hot, two adjust the packaging machine winding spring, align the packaging roll.

5. The packing roll cannot be sealed (generally, the long side of the package is divided, the short side is divided, and the divided side is judged to be inside and outside according to the bag that comes down) as shown in the figure: (The four big screws on the side of the head, the top two are edge sealing and top silk, the top is the inside edge of the inside tube, and the top is the outside edge of the outside tube; The following two are sealing top wires)

Maintenance measures: first, replace the heating pipe, and second, adjust the dividing wire (generally, as long as there is room to seal the dividing pipe, this situation is normal for the heating pipe). You can screw in one circle at a time until it is adjusted well (Note: it is recommended not to screw in too much, too much twisting may crush the packaging roll, the same as below).

The edge cannot be pressed down

Maintenance measures: find out whether it is impossible to press on the inside or the outside, and then screw the corresponding screws in (screw too tight will cause the bag to run away, it is recommended that the main), the heating tube is broken may also appear edge sealing

6 Packaging roll deviation or wrinkled

Maintenance measures: find the sealing or sealing, by the inside side or by the outside side, and then loosen the top wire (appropriate debugging, too much will not be sealed,) take out the spring inside the top wire and install it from the new (the machine is too old spring will lose elasticity, which helps to restore)

7. Maintenance measures for temperature problems: adjust the packaging temperature (the overall wrinkling of the packaging roll can reduce the temperature; If the packing volume cannot be sealed, the temperature can be raised. It is recommended to adjust the temperature to 5 degrees and keep the temperature stable for 20 minutes before packaging (temperature 130 < actual temperature > 101, the sealing will stop heating if the temperature exceeds 130).

In addition, the sealing can not be adjusted to compensate the temperature, press and hold down the zero key, and then according to the temperature will appear a number, (8 as the standard) Summary: packaging problem is mainly packaging volume problem, debugging first adjust the temperature, and then adjust the other (general factory machine has been adjusted, it is recommended not to adjust randomly, customers only need to maintain correct operation and maintenance)